Electronics Manufacturing Energy Audit

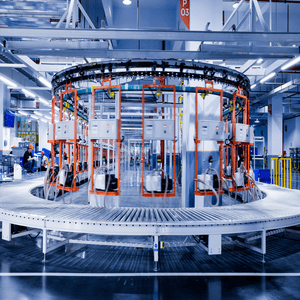

Comprehensive Level 2 energy audit for a large manufacturing facility producing thin film, ceramic fuses, and reed switches. The project assessed HVAC, compressed air, nitrogen generation, water treatment, and lighting systems, identifying opportunities to improve efficiency, reduce operational energy use, and lower carbon emissions while maintaining production quality and reliability.

Detailed Assessment

- Evaluated AHUs, MAUs, chillers, pumps, and associated controls.

- Reviewed compressed air and vacuum systems for leaks, control optimization, and load management.

- Assessed water treatment plant energy use and efficiency improvements.

- Analyzed nitrogen generator operation and opportunities for lower-pressure optimization.

- Conducted facility-wide lighting assessment, including offices and production areas.

Performance Evaluation

- Recommissioned and optimized chiller plant, AHUs, MAUs, and process cooling systems.

- Installed actuators, dynamic balancing valves, and VSDs on pumps and fans.

- Performed cooling tower descaling and water treatment upgrades.

- Optimized compressed air with pressure reduction, booster installation, and high-efficiency compressor replacement.

- Implemented heat recovery systems for ventilation units.

- Replaced degraded insulation and transitioned to centralized chiller systems.

- Upgraded lighting from fluorescent to LED.

Diagnostic Testing

- Tested and recalibrated cooling and ventilation controls.

- Performed leak detection and flow measurement for compressed air networks.

- Used thermal imaging and airflow verification for duct and coil insulation.

Maintenance Review

- Developed preventive maintenance plans for chillers, pumps, compressors, and ventilation equipment.

- Trained operations staff on optimized control sequences and monitoring tools.

- Established procedures for sustained performance tracking and periodic recommissioning.

System Optimization

- Implemented load-based operation of cooling and compressed air systems to reduce part-load inefficiencies.

- Integrated heat recovery for process and ventilation air.

- Optimized BMS programming for efficient scheduling and setpoint control.

Efficiency Improvement

- Estimated Annual Energy Savings: 2,192 MWh.

- CO₂ Emissions Reduction: 1,407 tonnes/year.

Result: A comprehensive set of targeted measures delivering significant energy savings, improved operational stability, and reduced environmental impact, without compromising the stringent operational requirements of a high-precision manufacturing environment.