Textile Printing Facility – Energy Audit and Decarbonization Plan

A comprehensive ASHRAE Level 2 Energy Audit combined with a Decarbonization Plan for a textile printing facility specializing in transfer printing on fabrics. The assessment identified opportunities to eliminate steam use, improve process efficiency, and support compliance with international supply chain environmental requirements. Priority actions focused on electrifying printing processes, optimizing support systems, and enhancing energy management capabilities.

- Baseline energy mix included both electricity and steam, with printing operations as the largest energy consumer.

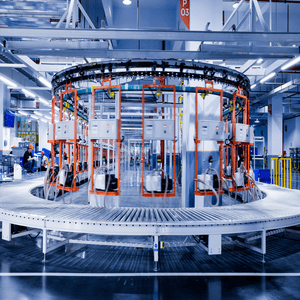

- Evaluation of printing lines, ventilation, motor systems, calender machines, and compressed air operations.

- Identification of inefficiencies in system controls, equipment operation, and thermal management.

- Electrification of printing lines to replace steam-based processes.

- Load-based ventilation control via variable frequency drives (VFDs).

- Upgrades to high-efficiency motors.

- Improved thermal insulation on process equipment.

- Installation of smart energy metering for real-time performance monitoring.

- Compressed air system optimization.

- Removal of unnecessary thermal storage to reduce standby losses.

- Energy use mapping across all major processes.

- Measurement and verification of system loads.

- Compressed air leak detection and purge cycle assessment.

- Updated preventive maintenance protocols for motors, fans, and compressed air equipment.

- Staff training on optimized controls and monitoring tools.

- Regular energy performance reviews aligned with sustainability targets.

- Full electrification of key processes to remove steam dependency.

- Demand-based control for ventilation and compressed air.

- Integration of real-time monitoring for continuous improvement.

- Estimated annual energy savings: ~556 MWh/year (≈26% of total energy use).

- Estimated annual CO₂ reduction: ~141 tCO₂/year (≈23% reduction).

- Medium–long term: up to ~90% CO₂ reduction via full electrification of remaining processes and renewable electricity procurement.

Result: A targeted efficiency and decarbonization strategy delivering immediate operational savings of over 500 MWh/year and 140 tonnes of CO₂ annually, while establishing a clear roadmap for deeper carbon cuts through electrification, renewable energy integration, and advanced monitoring.