Abstract

André Missenard (1901–1989) was a French engineer whose pioneering work on thermal comfort remains embedded in the very fabric of modern building standards. Decades before the international adoption of the PMV/PPD model and ASHRAE’s global reach, Missenard introduced concepts and tools that directly shaped the way engineers understand, measure, and deliver comfort indoors.

From his early career in hydraulic heating networks, through the creation of the temperature résultante and the degré Missenard, to the development of practical instruments like the Missenard thermometer, his approach was rooted in physical measurement and operational reality. Crucially, his methods integrated radiant temperature—the influence of surrounding surfaces—into comfort assessment, an element often overlooked in earlier Anglo-American models.

This article traces Missenard’s career chronologically, exploring his influence on European norms, the bridge to Fanger’s predictive model, and the subsequent integration into ASHRAE standards. Along the way, we revisit the elegance of his graphical tools, the institutions that preserved his legacy, and the enduring relevance of his insights for modern renovation and decarbonisation of buildings.

Prologue — My First Encounters with Missenard

I first met André Missenard not in the pages of a comfort standard, but in the pipes and pumps of my early industrial engineering courses. In those years, Missenard was a name attached to hydraulic diagrams—circuits for hot-water heating, thermosiphon loops, pump curves, and the stubborn equations of pressure drops. He appeared in the context of distribution: how to get hot water to every emitter with the right flow, the right temperature, and minimal wasted energy. Comfort was there in the background, but it seemed an abstract end to a very mechanical means.

It was years later, during my specialisation in building renovation and energy efficiency, that Missenard returned—this time as a central figure in a module on comfort and health taught by Stéphane Lassue. Here, the emphasis was no longer on pipe runs but on people: how we feel in a space, why two rooms at the same air temperature can feel worlds apart, and how to quantify that difference.

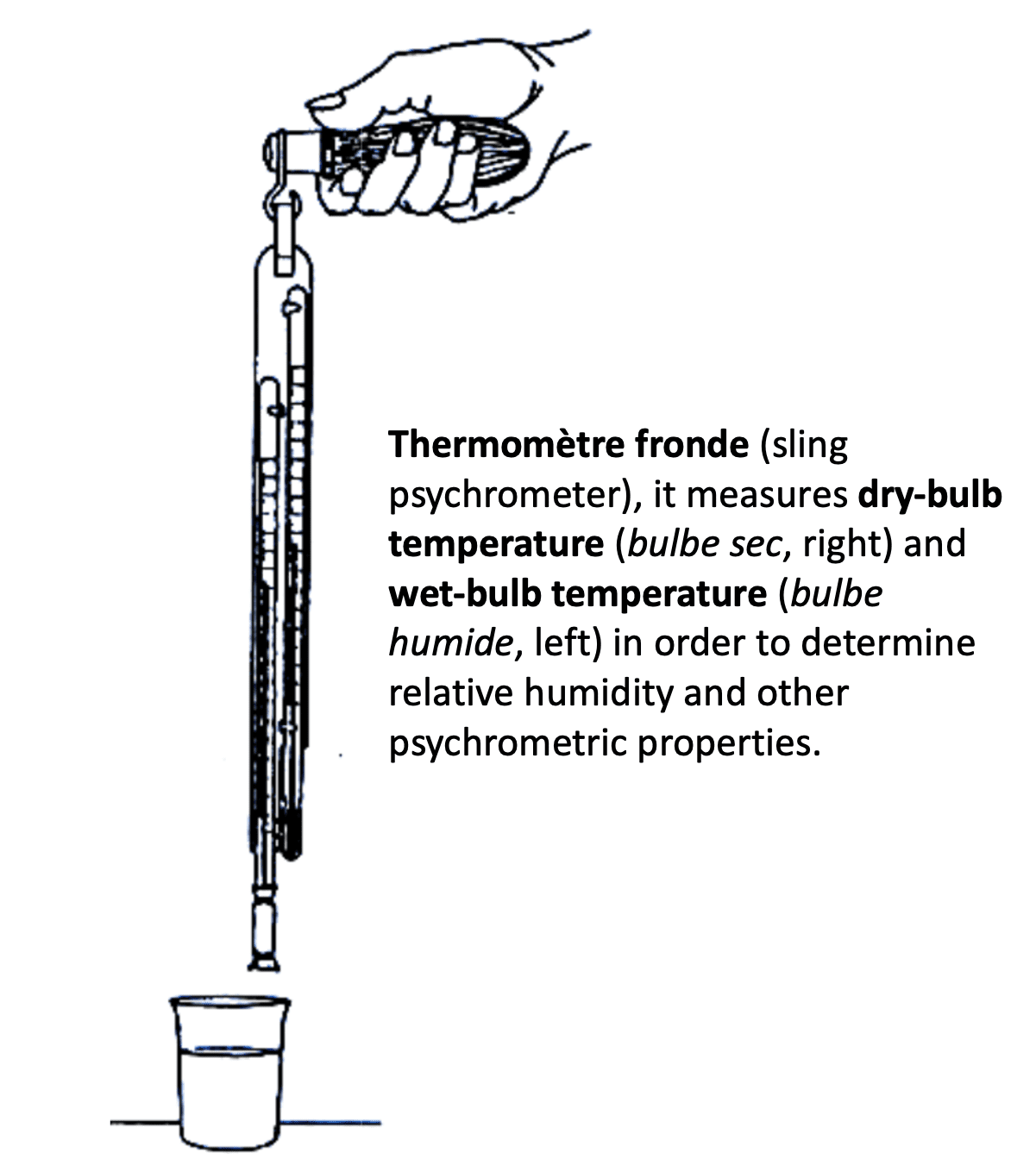

Lassue introduced us to Missenard’s température résultante, a measure that blends air temperature with the average radiant temperature of surrounding surfaces (Missenard, 1933). Suddenly, walls, floors, ceilings—the silent companions in any room—became active players in comfort. The cold sheen of an uninsulated wall could drag the température résultante down by several degrees, producing discomfort even if the air was at 20 °C. This was no theoretical flourish: Missenard had provided tables and formulas to account for it, along with a simple, purpose-built instrument—the Missenard thermometer—to read it on site.

This is where I began to see the elegance of his approach. Unlike purely theoretical models, Missenard’s method was operational. You could take measurements in a lived-in space, read them against his graphical nomograms—still striking today in their clarity—and translate them into actionable design or retrofit choices. No laboratory required.

Even the terminology carried a certain engineering poetry. The degré Missenard—literally “Missenard degree”—was shorthand for the température résultante adjusted for humidity and air movement. It bridged the gap between what a thermometer reads and what the body feels.

What I did not know then was how far-reaching this work would be. The concept of température résultante is mathematically equivalent to what would later be called “operative temperature” in European and Scandinavian research, and it feeds directly into the core equations of the PMV/PPD model developed by Danish researcher P.O. Fanger in the late 1960s (Fanger, 1970). By the time ASHRAE adopted PMV/PPD into Standard 55, Missenard’s influence was embedded—though rarely named—in the global language of comfort.

In this article, I will trace that journey: from a young French engineer balancing flows in heating pipes, to a pioneer who taught the world to measure not just the warmth of the air, but the warmth of the room itself.

I — Before Missenard: The Context (1900–1932)

When André Missenard began his career in the late 1920s, the science of thermal comfort was still in its formative years. Engineers had mastered the basics of generating and distributing heat—steam boilers, low-pressure hot water systems, coal-fired plant rooms—but the prevailing design philosophy was still overwhelmingly focused on air temperature. The dominant assumption was that if the air was at the “right” temperature, the occupants would be comfortable.

Yet even in the early 20th century, practitioners knew from experience that this was not always true. A draughty salon with a roaring radiator could feel cold if the walls were uninsulated. Conversely, a sun-drenched room might feel warm with minimal heating. The missing factor was radiant temperature—the heat exchanged between the human body and surrounding surfaces by infrared radiation.

Early comfort indices in the US

In 1923, two American engineers, Houghton and Yaglou, published their work on the effective temperature index (Houghton & Yaglou, 1923). Their method combined dry-bulb air temperature and relative humidity into a single scale to predict thermal sensation. It was an important advance in recognising that humidity altered perceived comfort—dry air in winter feels cooler, humid air in summer feels warmer—but it still treated the radiant environment as a negligible factor.

This omission meant that two rooms at identical “effective temperatures” could feel very different if their wall, floor, or ceiling temperatures diverged. In the American context of the time—office buildings with central heating and modest insulation—this simplification was serviceable, but it was blind to a fundamental physical reality: the human body exchanges as much heat by radiation to surrounding surfaces as it does by convection to the air.

The British black globe

In the United Kingdom, the concern for radiation appeared in occupational hygiene and environmental physiology. In the early 1930s, T. H. Vernon developed the black globe thermometer (Vernon, 1930) to quantify radiant heat exposure in industrial and military contexts. His instrument was a hollow copper sphere, painted matte black, enclosing a thermometer. By absorbing radiant energy and exchanging heat with the surrounding air, the black globe reached a temperature somewhere between the air temperature and the mean radiant temperature (MRT) of the environment.

The black globe was a breakthrough in measuring the combined effect of air and radiation, but it was slow to stabilise and primarily used in laboratory or field-study contexts—not in everyday building design.

Bedford’s refinements in the US

In 1940, H. T. Bedford at the US National Bureau of Standards refined the globe method for thermal comfort research (Bedford, 1940). His work improved calibration and interpretation, linking globe temperature readings with subjective comfort votes. Yet Bedford’s sphere remained a research tool, applied mainly in controlled studies or industrial hygiene, not a standard fixture in architectural practice.

Why building design lagged behind

By the late 1920s, central heating systems were widespread in Europe and North America. Design codes specified air temperatures for various building types, but virtually no guidance existed for accounting for cold walls, radiant asymmetry, or combined air-radiant effects in occupied rooms. The tools and indices emerging from the UK and US were valuable, but they were either:

- Too narrow — focusing on humidity and air temperature without radiation (effective temperature), or

- Too specialised — black globe thermometers suited for laboratory use, not for quick, on-site building diagnostics.

This left a gap for an engineer who could bridge operational practicality with physical completeness—someone who could devise a method to measure comfort in real rooms, quickly, with tools that could be used by heating engineers and building inspectors.

The French context: COSTIC and Quint & Flamant

France in the 1920s had its own ecosystem of heating expertise, centred on firms like Quint & Flamant and institutions like the Comité Scientifique et Technique des Industries Climatiques (COSTIC), founded in 1928. COSTIC’s mission was to unify technical knowledge in heating, ventilation, and air treatment, publish standard methods, and train engineers.

When Missenard entered this environment in 1926, he was working in an industry that was both technically mature in hydraulics and distribution, and conceptually ready for a leap in comfort science. The French tradition placed strong emphasis on measurement and operational diagnosis, which meant that any new comfort method would have to work not only in a lab, but also on a cold February morning in a Haussmann apartment.

Why Missenard’s leap was possible in France

- Mixed building stock: from poorly insulated 19th-century masonry to modernist concrete, offering a wide variety of radiant conditions.

- Strong hydraulic expertise: circulating hot-water systems were common, giving engineers control over emitter types and placement.

- Measurement culture: COSTIC encouraged practical diagnostic tools, not just theoretical guidelines.

In this setting, the shortcomings of “air temperature only” comfort design were glaring. French engineers needed a way to quantify the effect of cold walls, warm floors, or radiant panels and to relate those measurements directly to perceived comfort. This is precisely the gap Missenard would fill starting in 1933, by marrying physical completeness (air + radiation + humidity + air velocity) with operational usability (instruments, nomograms, field methods).

II — Formation of an Engineer of the Field (1920–1932)

André Missenard was born in 1901, into a France that was about to see vast transformations in both technology and building comfort. By the time he entered professional life, the First World War had accelerated advances in materials, mechanical systems, and heating technology. Paris and other major cities were expanding, and large building projects demanded not just architectural flair but modern, reliable heating.

From engineering education to heating industry

After his technical studies, Missenard joined Quint & Flamant in 1926, one of France’s leading firms in heating and climate control. Here, he immersed himself in the hydraulics of hot-water heating systems—a subject that was, in many ways, the backbone of thermal comfort delivery.

In the late 1920s, French heating engineers were mastering the shift from purely gravity-driven thermosiphon systems to pumped circulation. Thermosiphons relied on density differences between hot and cold water to drive flow; they required meticulous attention to pipe gradients, diameters, and minimal restrictions. Pumped systems offered more flexibility, but also brought new challenges: controlling flow rates, balancing circuits, and avoiding noise and uneven heating.

Missenard distinguished himself by approaching these systems not only as mechanical circuits but as comfort delivery networks. The goal, in his mind, was not simply to get water from the boiler to the radiator, but to ensure that the heat actually produced the desired comfort in the room.

COSTIC and the culture of operational science

It was around this time that Missenard became closely involved with the Comité Scientifique et Technique des Industries Climatiques (COSTIC), founded in 1928. COSTIC was both a research hub and a technical training centre for the heating and ventilation industry. Its philosophy was distinctly pragmatic: knowledge had to be usable by practitioners in the field, not just in laboratory reports.

This was entirely in line with Missenard’s mindset. He had little interest in comfort theories that could not be translated into on-site measurements and actionable design changes. COSTIC provided the perfect platform for him to test ideas, share findings, and teach methods that combined physics with field practicality.

Early hints of the comfort question

In these years, Missenard was already noticing that many well-designed hydraulic systems—perfect on paper—failed to satisfy occupants. The most common complaint? “It feels cold in here”, even when the thermometer on the wall read the specified 20 °C.

From an engineering perspective, the issue often came down to cold radiant surfaces. A corner flat in Paris with two external walls could have radiators delivering exactly the calculated heat load, but the mean radiant temperature in the seating zone might be far lower than in a central apartment. The occupants felt a persistent chill, especially in winter evenings when walls cooled rapidly after sunset.

At the time, neither French nor international heating design standards provided a way to quantify this effect directly in the field. Radiant exchange was discussed in academic physics, but not in routine heating calculations. Missenard began to suspect that any realistic measure of comfort would need to account for it.

Hydraulic precision meets radiant awareness

His hydraulic training gave him a unique perspective. Where others saw “the air is 20 °C, job done”, Missenard saw a two-stage problem:

- Distribution: get the right heat output into the room (hydraulic design, emitter sizing).

- Integration: ensure that this heat raised both the air temperature and the surface temperatures to levels that would result in genuine comfort.

He also realised that some heating strategies—like underfloor heating—could produce higher mean radiant temperatures at lower air temperatures, delivering comfort more efficiently. This observation would later shape his advocacy for low-temperature radiant systems decades before they became mainstream.

Seeds of a measurement method

By the early 1930s, Missenard was convinced that an engineer needed a simple, robust way to measure the combined effect of air temperature and radiant environment. He wanted something as straightforward as a pressure gauge for hydraulics—something that could be read on site, without complex setup, and that could directly inform design or adjustment decisions.

The black globe thermometer existed, but it was too slow and cumbersome for quick building checks. Missenard began experimenting with adapted thermometers and nomograms that could relate straightforward readings to a comfort index. These experiments would culminate, in 1933, in the publication of his first formal description of the température résultante (Missenard, 1933)—a concept that would anchor the rest of his career.

III — The Breakthrough: Resultant Temperature & the Missenard Degree (1933–1937)

By 1933, André Missenard was ready to make his move. Years of hydraulic work had taught him that even the best-balanced circuits could leave people cold if the room’s surfaces were cold. His thinking crystallised into a deceptively simple question: How can we measure, in one number, the thermal environment as it is truly felt by an occupant?

Defining the température résultante

In a landmark publication, Température effective d’une atmosphère. Généralisation température résultante d’un milieu (Missenard, 1933), he proposed an index that combined:

- The air temperature (T_air), which affects convective heat exchange with the body.

- The mean radiant temperature (T_radiant), the average temperature of surrounding surfaces weighted by their angle and emissivity.

The simplest form of his equation, for still air, was:

\[ T_{\mathrm{res}}=\frac{T_{\mathrm{air}}+T_{\mathrm{radiant}}}{2} \]

But Missenard’s genius was not in this basic average—it was in the operationalisation. He provided methods to measure these quantities quickly in the field, and tools to adjust them for other environmental factors.

Mean radiant temperature made practical

Measuring mean radiant temperature in 1933 was not trivial. The black globe thermometer existed in the UK, but Missenard wanted something faster and more compact. He designed the thermomètre de Missenard: essentially a thermometer enclosed in a small blackened shell, with characteristics tuned to respond both to air temperature and to radiant temperature in a predictable proportion.

The device was paired with calibration curves so that a field engineer could read the combined effect without lengthy calculations. This was a decisive difference from the British black globe—it was portable, faster to stabilise, and tailored for building diagnostics rather than laboratory studies.

From température résultante to degré Missenard

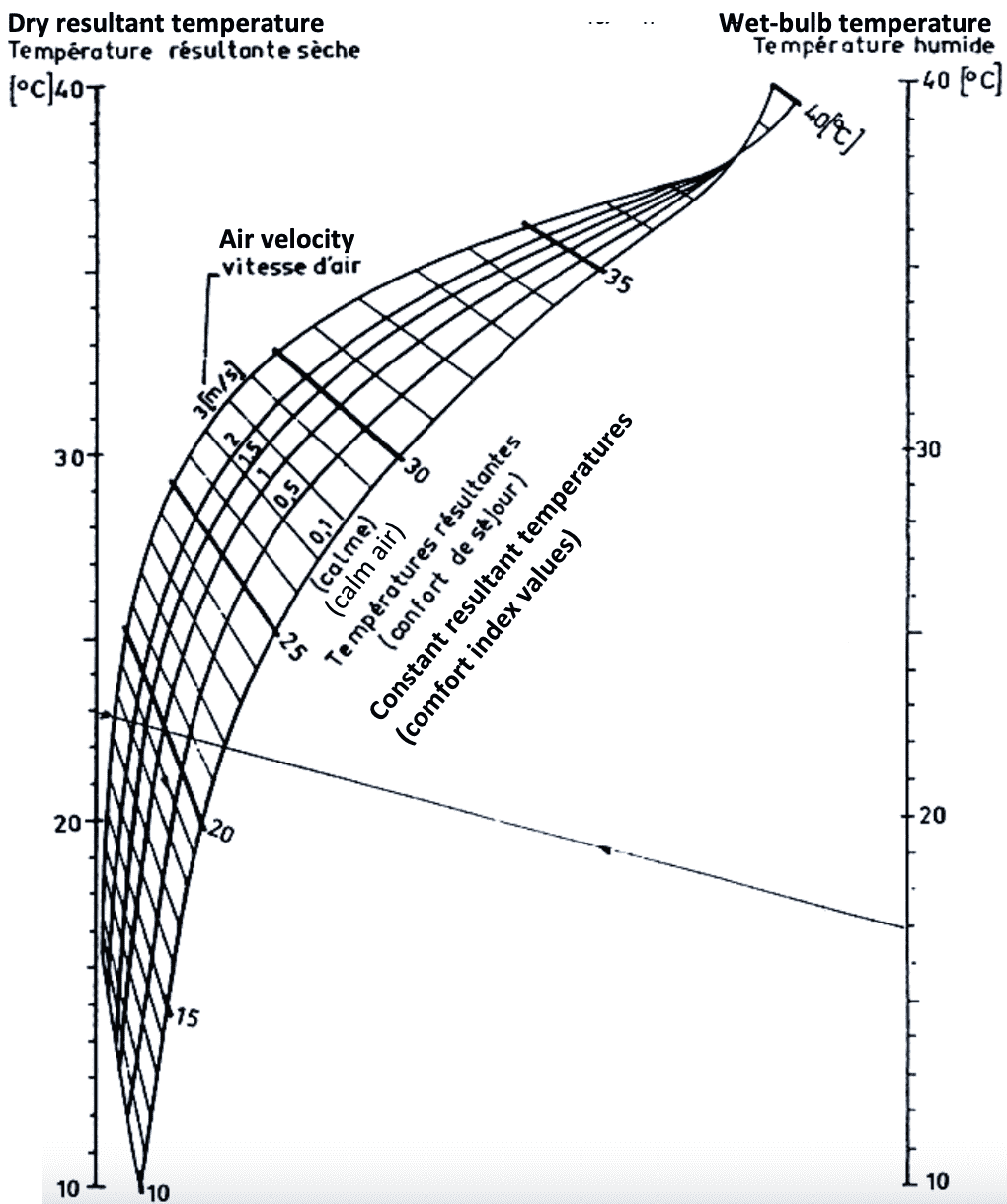

Missenard’s next step was to recognise that T_res was not enough. Comfort also depends on air velocity and humidity, both of which alter convective and evaporative heat loss from the body. So he created the degré Missenard (°M), which started with T_res and applied corrections based on measured humidity and air speed.

For example, in a cool, draughty room with a T_res of 19 °C, the perceived comfort might correspond to only 17 °C on the °M scale. Conversely, in warm, humid conditions, °M could be higher than T_res.

He published nomograms—graphical tools where the engineer could connect measured air temperature, globe temperature, humidity, and air speed to find °M directly. These diagrams were not only functional but visually elegant: clean lines, logical scaling, and minimal clutter. They were meant to be used with a pencil in hand, often on site.

(Missenard, 1935) further refined the approach, providing detailed tables for various building types and seasons.

Anecdote: the draughty Parisian salon

One oft-cited training example from COSTIC’s later materials illustrates Missenard’s thinking:

- Air temperature: 20 °C

- Mean radiant temperature: 14 °C (due to two uninsulated external walls)

- Air velocity: 0.15 m/s

- Relative humidity: 50 %

From this, T_res = (20 + 14)/2 = 17 °C. Applying Missenard’s humidity and velocity corrections, °M ≈ 16.5 °C. The occupants’ complaint—“We feel cold”—was thus quantified, and the solution (insulating the walls or introducing radiant panels) became obvious.

Integration into design practice

By the late 1930s, Missenard’s method had been adopted in French heating design guides. A typical process now involved:

- Hydraulic design: ensure correct flow and emitter sizing.

- Comfort check: estimate T_res based on expected surface and air temperatures.

- Adjustment: modify emitter type, placement, or insulation to raise T_res into the comfort range.

This integration meant that French heating engineers were explicitly designing for combined air-radiant comfort decades before such considerations became standard in other countries.

How this prefigured “operative temperature”

In modern terminology, T_res is effectively equivalent to operative temperature—the average of air and mean radiant temperatures, weighted by their respective heat transfer coefficients. This equivalence is explicitly acknowledged in later European standards and ASHRAE documentation (ASHRAE, 2017).

The key difference is that Missenard’s version was embedded in a practical measurement and correction framework. Operative temperature as defined later was a purely physical quantity; °M was a field engineer’s comfort index.

A bridge to predictive modelling

While Missenard stopped short of creating a fully predictive statistical model like P.O. Fanger would in the 1970s, his °M index contained the essential environmental inputs—air temperature, radiant temperature, humidity, air velocity—that Fanger would feed into his PMV (Predicted Mean Vote) equation (Fanger, 1970). In this sense, Missenard built the measuring stick that Fanger later turned into a predictive scale.

1937: practical applications multiply

By 1937, COSTIC training materials included the Missenard thermometer, °M nomograms, and T_res calculation methods as standard teaching. Heating contractors were encouraged to carry the thermometer on site visits, especially when diagnosing comfort complaints.

In the context of 1930s building stock—with its mix of solid masonry, thin single glazing, and uninsulated roofs—this was transformative. It gave engineers a language and a tool to explain to clients why comfort was lacking, and how targeted improvements could fix it.

IV — Hydraulics → Emission → Comfort: The Missenard School (1930s–1950s)

If Missenard’s température résultante was the intellectual core of his comfort philosophy, hydraulics was the skeleton and muscle that made it work. He never saw heat generation, distribution, and emission as separate disciplines; in his mind, they were parts of a single system with one purpose: to produce comfort where people actually lived and worked.

The two-stage problem

Missenard’s hydraulic background meant that he instinctively thought in two stages:

- Distribution — ensuring the right amount of heat reached each emitter, with stable flows and minimal losses.

- Integration — ensuring that the emitter’s heat output raised both the air temperature and the surface temperatures in the occupied zone to a level that delivered comfort, as quantified by the °M index.

This was a subtle but important departure from much of the heating practice of the time, which often ended the calculation at the radiator output or the nominal air temperature in the room.

Radiator placement and radiant balance

Missenard was keenly aware of how emitter placement influenced radiant balance. A radiator placed under a window offset the radiant chill from the glass. A wall radiator could raise the mean radiant temperature of a cold partition. Conversely, a poorly placed emitter could leave parts of the body “radiatively cold” even in warm air.

By introducing T_res and °M into design checks, he gave engineers a quantitative reason to position and size emitters with radiant comfort in mind.

Early advocacy for radiant systems

Perhaps the most forward-looking element of Missenard’s work was his promotion of low-temperature radiant systems—what we now call underfloor heating, heated ceilings, and radiant wall panels.

Although radiant floor heating in a rudimentary form had existed for centuries (e.g., Roman hypocausts), the modern hydronic version was still experimental in the 1930s. In France, Missenard was one of the first to document and standardise its design for comfort.

In his technical writings and COSTIC courses from the late 1930s onwards, he outlined:

- Maximum surface temperatures (typically 28–30 °C for floors) to avoid discomfort to the feet.

- Pipe spacing and water temperature to ensure uniform heat distribution.

- Thermal inertia considerations—slow response times were both a feature (stable comfort) and a limitation (sluggish control).

- How radiant floors could achieve a high °M at a lower T_air, thus saving energy while maintaining comfort (Missenard, 1938).

Hydraulics enabling comfort

For Missenard, radiant systems were not just a comfort upgrade—they were a hydraulic challenge. Floor circuits required careful balancing to ensure uniform temperatures, particularly in gravity-fed or early pumped systems. His design tables for pipe diameters, flow rates, and circuit lengths became reference points in French practice.

This was again part of his integrated approach:

- Comfort target: specify a desired °M.

- Emission strategy: choose emitter types and positions to achieve it.

- Hydraulic design: size and balance the network to deliver the required water temperatures and flows.

Anecdote: the “warm feet, cool head” demonstration

COSTIC training in the 1950s included a demonstration inspired by Missenard’s lectures: two identical test rooms, one heated by radiators at 22 °C air temperature, the other by an underfloor system at 19 °C air temperature but higher mean radiant temperature. Occupants reported greater comfort in the latter, even though the air was cooler. The °M measurements explained why: the floor-heated room’s T_res matched or exceeded the radiator room’s despite lower T_air.

Plancher chauffant: pioneer, not sole inventor

It is important to be precise: Missenard did not invent the concept of underfloor heating globally—patents and prototypes existed in Germany, the UK, and the US earlier in the 20th century. But he was a pioneer in France, and arguably the first to anchor it explicitly in a quantitative comfort framework. His work made the link between hydraulic design, radiant balance, and measured °M explicit.

Extending to other radiant solutions

Beyond floors, Missenard explored:

- Radiant ceilings—effective in spaces where wall and floor heating were impractical.

- Radiant wall panels—particularly in retrofits where external walls were cold.

- Mixed systems—radiators supplemented by radiant panels to correct cold-surface asymmetries.

In all cases, his guiding metric was °M, allowing objective comparison between systems.

Influence on French building culture

By embedding °M into the workflow of heating engineers, Missenard subtly shifted the culture of French building services:

- Engineers began to think of comfort as a measurable deliverable, not just a by-product of heating.

- Hydraulics and comfort became two sides of the same design process.

- Radiant solutions gained legitimacy not as “luxuries” but as efficient ways to meet comfort targets.

This mindset persisted through the post-war reconstruction boom, influencing how public buildings, housing blocks, and schools were designed and heated.

V — Diffusion in France and Europe (1940s–1960s)

By the early 1940s, André Missenard’s ideas had moved beyond personal research and into the bloodstream of French building services engineering. This was not accidental—it was the result of deliberate institutional adoption, primarily through COSTIC, the AFNOR standards body, and, later, the Centre Scientifique et Technique du Bâtiment (CSTB).

COSTIC as amplifier

COSTIC had been founded in 1928 to unify the heating, ventilation, and air treatment industries under a common technical language. By the 1940s, it had become a recognised authority in France for both training and technical guidance.

Missenard’s association with COSTIC meant that his température résultante and degré Missenard were taught directly to practising engineers and technicians, not just published in specialist journals. The COSTIC bulletins of the 1940s and 1950s include nomograms, worked examples, and guidance on instrument calibration (COSTIC Bulletin, 1948). Field engineers were encouraged to carry the Missenard thermometer on diagnostic visits, especially when client complaints involved “feeling cold” despite apparently adequate heating.

AFNOR standardisation

In the post-war period, the Association Française de Normalisation (AFNOR) began codifying building services calculations, partly to support the vast reconstruction effort after WWII. AFNOR documents from the 1950s incorporated température résultante into comfort assessment for certain building categories (AFNOR NF X35, 1956). This was significant: it meant that in France, by mid-century, the combined air–radiant temperature concept was not an optional refinement—it was part of the official design criteria.

CSTB and research integration

The CSTB, created in 1947, became the national hub for building science. While its early focus was on materials and structural engineering, by the late 1950s it had absorbed environmental comfort into its research scope. CSTB publications of the era cite °M alongside operative temperature in European research, acknowledging their practical equivalence (CSTB Rapport, 1959).

This institutional ecosystem—COSTIC for training, AFNOR for standardisation, CSTB for research—ensured that Missenard’s work did not remain a personal curiosity. It became the default approach for thermal comfort assessment in French building practice.

The Scandinavian and German uptake

Meanwhile, in Scandinavia and Germany, a parallel vocabulary was emerging. Researchers there were adopting the term operative temperature (operative Temperatur in German, operativ temperatur in Swedish/Danish) to describe what was physically equivalent to Missenard’s température résultante:

\[ T_{\mathrm{op}}=\frac{h_c\,T_{\mathrm{air}}+h_r\,T_{\mathrm{radiant}}}{h_c+h_r} \]

where h_c is the convective heat transfer coefficient and h_r the radiative coefficient.

The difference was mostly one of emphasis:

- Missenard embedded the measure in a practical index (°M) with humidity and airspeed corrections, designed for quick field use.

- Scandinavian/German researchers framed it in terms of heat transfer coefficients, aligning it with laboratory and theoretical modelling.

By the early 1960s, Scandinavian building codes referenced operative temperature directly, especially for spaces where radiant asymmetries were likely (e.g., glazed facades, industrial halls).

Cross-pollination without attribution

It is hard to pin down exactly how Missenard’s ideas migrated north. French technical literature was read in specialist circles in Scandinavia and Germany, and COSTIC maintained ties with European counterparts. However, language barriers and different research cultures meant that the term température résultante rarely appeared in non-French publications, even when the physical quantity was the same.

The operative temperature metric would later be adopted by the International Organization for Standardization (ISO) and by ASHRAE in the US—effectively globalising the concept without retaining its French origin.

Why France moved earlier than others

- Building stock diversity — post-war reconstruction combined with older, poorly insulated buildings created a high demand for accurate comfort diagnostics.

- Industry training culture — COSTIC ensured that engineers were not just aware of °M, but trained to use it routinely.

- National standardisation drive — AFNOR’s post-war codes sought to unify practice quickly, giving practical methods like °M an official status.

By the time P.O. Fanger began formulating his PMV/PPD model in Denmark in the late 1960s, température résultante was already standard vocabulary for thousands of French engineers.

VI — From Measurements to Models: Fanger and PMV/PPD (1960–1970)

By the early 1960s, the parameters that André Missenard had been promoting for three decades—air temperature, mean radiant temperature, humidity, and air velocity—were embedded in French engineering practice. Across the North Sea, in Denmark, a young researcher named Poul Ole Fanger was preparing to take these same variables and do something different: build a fully predictive mathematical model of human thermal sensation.

The Fanger project

At the Technical University of Denmark, Fanger embarked on a series of controlled climate chamber experiments in the 1960s. His aim was ambitious: not just to describe comfort in terms of environmental conditions, but to predict, with statistical reliability, how a given group of people would vote on their comfort in a given environment (Fanger, 1970).

To do this, he had to measure the same fundamental environmental variables Missenard had long emphasised:

- T_air — dry-bulb air temperature.

- T_radiant — mean radiant temperature of surrounding surfaces.

- v_air — air velocity in the occupied zone.

- RH — relative humidity.

But Fanger added two physiological parameters that Missenard’s °M did not directly include:

- M — metabolic rate, in met units, representing the internal heat production of the human body.

- I_cl — clothing insulation, in clo units, representing the thermal resistance of clothing layers.

These additions allowed him to construct a heat balance equation for the human body, accounting for all modes of heat transfer—convection, radiation, evaporation, and conduction.

Fanger’s Comfort Equation

Key Terms

- Clothing parameters:

\( I_{cl} \) = Clothing insulation (clo)

\( f_{cl} \) = Ratio of clothed to nude surface area

- Activity-related terms:

\( H \) = Metabolic heat production (W/m²)

\( M \) = Mechanical work (external work) (W/m²)

- Environmental variables:

\( T_a \) = Air temperature (°C)

\( T_r \) = Mean radiant temperature (°C)

\( v \) = Relative air speed (m/s)

\( P_a \) = Water vapor pressure (mb)

- Convective heat transfer coefficient: \( h_c \) (W/m²·K)

Fanger’s Equation

\( I_{cl} \) = Clothing insulation (clo)

\( f_{cl} \) = Ratio of clothed to nude surface area

\( H \) = Metabolic heat production (W/m²)

\( M \) = Mechanical work (external work) (W/m²)

\( T_a \) = Air temperature (°C)

\( T_r \) = Mean radiant temperature (°C)

\( v \) = Relative air speed (m/s)

\( P_a \) = Water vapor pressure (mb)

The following equation represents the energy balance on the human body for thermal comfort estimation:

\[ H – 0.31(57.4 – 0.07H – P_a) – 0.42(H – 58) – 0.0017M(58.7 – P_a) – 0.0014M(34 – T_a) = \] \[ 3.9 \times 10^{-8} f_{cl} \left[ (T_{cl} + 273)^4 – (T_r + 273)^4 \right] + f_{cl} \cdot h_c (T_{cl} – T_a) \]PMV: Predicted Mean Vote

The result was the Predicted Mean Vote (PMV) equation, which predicts the average thermal sensation vote (on the ASHRAE 7-point scale from –3 cold to +3 hot) that a large group of people would give in a particular set of environmental and personal conditions. The PMV equation is complex, involving iterative solutions to balance heat gains and losses, but its environmental core—T_air, T_radiant, v_air, RH—is identical to Missenard’s input set.

The difference lies in what PMV does with them: where °M gives a corrected “felt temperature” for a given individual in given conditions, PMV estimates a statistical vote from a population.

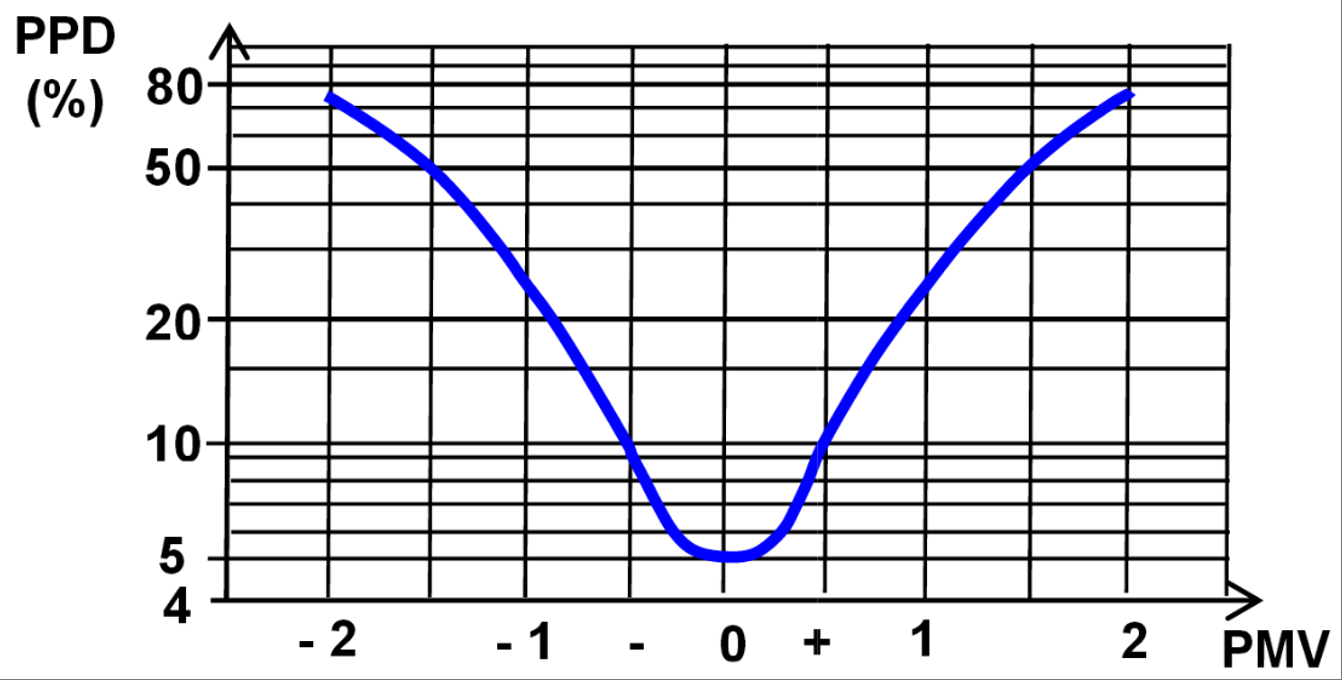

PPD: Predicted Percentage of Dissatisfied

Fanger also derived the Predicted Percentage of Dissatisfied (PPD) index, which translates PMV into the percentage of occupants likely to feel uncomfortably warm or cool. The PPD curve has a minimum of 5% dissatisfaction even at PMV = 0, recognising that no thermal environment pleases everyone.

Missenard’s indirect role

While Fanger’s publications rarely cite French sources directly, the operative temperature term in his model is physically equivalent to Missenard’s température résultante, and the use of combined air and radiant temperature in comfort prediction owes much to the earlier European diffusion of that concept (CSTB Rapport, 1959; ASHRAE, 2017).

In effect, Missenard’s work provided the measurement framework—how to capture T_air, T_radiant, RH, v_air reliably and in the field—while Fanger provided the predictive framework—how to use those variables in a statistical comfort model.

Why Fanger’s model spread internationally

- Language and publication — Fanger published in English at a time when English-language engineering journals were becoming dominant.

- Universality — PMV/PPD was presented as globally applicable, independent of national building traditions.

- Normative appeal — standards bodies could adopt PMV/PPD as a clear compliance target, expressed in percentages of satisfied occupants.

- Institutional backing — early adoption by the International Organization for Standardization (ISO) and later by ASHRAE gave the model global visibility.

What was gained—and lost

The move from °M to PMV/PPD brought several gains:

- Broader scope — clothing and metabolic rate allowed modelling of a wider range of activities and climates.

- Predictive power — designers could forecast comfort outcomes before building or renovating.

- Standardisation — a common global language for comfort.

But something was lost in translation: PMV/PPD is not an on-the-spot diagnostic tool. It requires multiple measurements and calculations—often impractical for rapid field troubleshooting. Missenard’s °M, by contrast, was designed to be used on site in minutes with a thermometer and an abacus-like nomogram.

A tale of two legacies

By the late 1970s, PMV/PPD had become the reference model in ISO 7730 and ASHRAE 55, while °M remained largely a French and francophone tool. Yet the DNA of Missenard’s method was present in every PMV/PPD calculation: without température résultante and its operational capture of radiant temperature, the PMV model would be blind to one of the most important drivers of comfort.

Fanger’s contribution was to universalise and codify the method; Missenard’s was to create it in a form that engineers could actually use on the ground. The two are not rivals but consecutive steps in the same evolution—from measurements that reflect reality to models that predict satisfaction.

VII — ASHRAE and the Globalisation of Comfort (1970–1990)

By the early 1970s, PMV/PPD had emerged from Denmark and begun its journey into the global regulatory framework. In the United States, the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) was looking to modernise its thermal comfort standards. ASHRAE Standard 55—first issued in 1966—originally offered relatively simple air temperature and humidity limits. But the appeal of a scientifically validated, internationally tested predictive model was hard to resist.

First encounters with PMV in ASHRAE

In the mid-1970s, ASHRAE technical committees began reviewing Fanger’s work (Fanger, 1970), along with supporting studies from the US National Bureau of Standards, to assess whether PMV/PPD could replace or augment the existing criteria. By 1981, PMV and PPD were formally incorporated into ASHRAE 55-1981, alongside simpler prescriptive methods. This gave US designers, for the first time, a probabilistic comfort target: Design for PMV between –0.5 and +0.5, yielding PPD ≤ 10%.

Operative temperature becomes standard

ASHRAE’s adoption also codified operative temperature—a term already used in Scandinavian and ISO contexts—as a valid design metric when radiant asymmetry and air movement were within limits (ASHRAE, 1981). In practice, operative temperature is physically equivalent to Missenard’s température résultante in still-air conditions. Yet in ASHRAE literature, the French origin of the concept was rarely acknowledged.

The US framing presented operative temperature as a “derived” measure from convective and radiative heat transfer coefficients—a more physics-lab description than Missenard’s field-ready °M index.

ISO alignment and mutual reinforcement

During the same period, the International Organization for Standardization was developing ISO 7730, first published in 1984, which adopted PMV/PPD as the primary comfort model. The near-simultaneous adoption by ASHRAE and ISO created a powerful mutual reinforcement: the US market saw ISO as a mark of global credibility, and ISO saw ASHRAE’s integration as proof of practical viability.

From this point forward, PMV/PPD became the de facto world standard for comfort assessment in climate-controlled buildings. Operative temperature survived as an alternative in specific cases, but always framed within the PMV/PPD paradigm.

The erasure of origins

By the late 1980s, English-language comfort literature—dominated by US and UK publications—largely omitted the history of température résultante. In many ASHRAE training materials, operative temperature is introduced without reference to earlier French or COSTIC work, giving the impression that it emerged independently in Anglo-Scandinavian research.

In reality, the chain of ideas is clear:

- Température résultante (Missenard, 1933) — French field method combining air and radiant temperatures.

- Operative temperature — formalised in Scandinavian/German research, physically equivalent.

- PMV/PPD — Fanger’s predictive model using the same environmental variables.

- ASHRAE 55 — US standard incorporating PMV/PPD and operative temperature.

Why ASHRAE’s adoption mattered

The US building services industry in the 1970s–80s was a massive exporter of standards and methods, both through international projects and through the American dominance of HVAC manufacturing. When ASHRAE adopted PMV/PPD, it didn’t just influence American buildings—it influenced engineering education, building codes, and product design globally.

This had a paradoxical effect: Missenard’s intellectual legacy reached more people than ever, but almost always without his name attached. The concepts lived on, stripped of their French origin story.

What remained uniquely French

Despite this globalisation, France continued to use °M in parallel with PMV/PPD, especially in renovation and field diagnostics. COSTIC training well into the 1990s still included the Missenard thermometer and nomograms, particularly for explaining comfort issues in older, naturally ventilated buildings where radiant losses were significant.

Thus, while ASHRAE and ISO drove a “top-down” adoption of PMV/PPD into new construction, °M persisted as a “bottom-up” tool in everyday engineering practice—exactly as Missenard intended.

VIII — Legacies and Misunderstandings

Any engineer whose work spans both practice and theory risks being remembered for less—or sometimes more—than they actually did. In the case of André Missenard, two recurring misconceptions appear in both technical folklore and casual conversation: that he invented the black globe thermometer, and that he invented underfloor heating. Both are inaccurate, but the truth is arguably more impressive.

The black globe myth

The black globe thermometer—a hollow metal sphere painted matte black to measure combined radiant and convective heat—predates Missenard. The earliest documented version is attributed to T.H. Vernon in the United Kingdom in the early 1930s (Vernon, 1930), with later refinements by H.T. Bedford in the United States (Bedford, 1940). These devices were developed primarily for occupational heat stress studies and environmental physiology, not for building heating design.

Missenard did not invent the black globe, but he adapted its principle into the thermomètre de Missenard, a faster-responding, smaller-scale instrument tailored for building diagnostics. He paired it with calibration tables and nomograms, making it a practical tool for field engineers. In doing so, he transformed a research device into an everyday engineering instrument—arguably a more influential contribution than simply inventing it.

The underfloor heating misconception

Hydronic underfloor heating in its modern form emerged from multiple sources in the early 20th century. Patents and prototypes appeared in Germany, the UK, and the US before Missenard addressed it. What Missenard did was to integrate it into a quantitative comfort framework.

In the late 1930s and 1940s, he published design limits for floor surface temperatures, methods for calculating pipe spacing and water temperatures, and guidance on controlling thermal inertia (Missenard, 1938). Crucially, he connected these design choices to the température résultante and the °M index—showing how radiant floors could achieve comfort at lower air temperatures, reducing energy consumption.

Thus, Missenard was not the inventor of underfloor heating, but he was a pioneer in its engineering validation for comfort, at least in France.

Why the attribution faded

- Language barrier — His key works were published in French and in French technical outlets, limiting their reach in the English-speaking world.

- Parallel development — Equivalent concepts (operative temperature) emerged in Scandinavia and Germany without explicit reference to France, creating the illusion of independent invention.

- Standardisation overshadowing — Once PMV/PPD and operative temperature entered ISO and ASHRAE standards, their historical roots were rarely discussed in training materials.

- Shift in emphasis — Global comfort discourse moved towards predictive modelling and away from simple measurement indices, reducing the visibility of °M.

What remains distinctively his

- Operationalisation of radiant temperature — He made it a standard field measurement for heating engineers, not just a research parameter.

- Integration of hydraulics and comfort — His designs linked distribution, emitter choice, and comfort targets in a unified workflow.

- Educational tools — The elegance and accessibility of his nomograms, still admired today, reflect a rare ability to merge science with usability.

- Persistent relevance in renovation — °M remains a go-to diagnostic tool in France, especially in older buildings where radiant losses dominate.

In short, Missenard’s legacy is not about singular inventions, but about translating complex physical principles into practical, reproducible engineering methods—and embedding them so deeply in practice that many engineers now apply them without knowing his name.

IX — Today: Relevance for Renovation and Decarbonisation

In the twenty-first century, the drive to decarbonise the built environment has brought thermal comfort back into focus—not as a luxury, but as a central metric of performance. Missenard’s ideas, developed in the 1930s for coal- and oil-heated buildings, turn out to be remarkably well-suited to the challenges of modern retrofits and low-carbon heating.

Why radiant temperature still matters

Most renovation projects face a common dilemma: the building’s heating system is upgraded or replaced, but the envelope remains thermally imperfect. Even with efficient heat sources—heat pumps, condensing boilers, district heating—the comfort outcome depends on more than just T_air.

In poorly insulated structures, the mean radiant temperature can lag far behind the air temperature in winter. Occupants may feel chilled near external walls or large glazed surfaces, leading to thermostat adjustments that drive up energy use. Missenard’s température résultante directly captures this effect, giving a more truthful measure of comfort than air temperature alone (Missenard, 1933).

Low-temperature systems and °M

The global shift towards low-temperature heat distribution—necessary for high-efficiency heat pumps and renewable sources—makes Missenard’s °M particularly relevant. A system designed around °M can deliver comfort at a lower T_air by increasing the radiant component, for example via:

- Underfloor or wall heating panels.

- Radiators with higher radiant fractions (e.g., larger surfaces, lower convection ratios).

- Strategic placement to address cold surfaces directly.

By targeting a desired °M rather than a fixed air temperature, designers can reduce supply water temperatures, improving system efficiency and lowering emissions.

Field diagnostics for renovation projects

One of Missenard’s greatest strengths was on-site applicability. The Missenard thermometer and nomograms remain a rapid way to:

- Measure T_air and T_radiant (via globe or adapted sensor).

- Correct for humidity and air velocity to get °M.

- Compare °M with comfort targets to identify whether discomfort is due to air, radiation, or both.

This diagnostic clarity is invaluable in renovation: it tells an engineer whether to prioritise envelope upgrades (to raise radiant temperature), distribution adjustments, or emitter replacement.

Comfort as an energy-saving measure

Modern policy frameworks often treat comfort as a “soft” metric compared to kilowatt-hours saved. But occupant comfort is directly linked to energy demand. If people feel cold due to low radiant temperatures, they will raise thermostats, extend heating hours, or block ventilation—all of which undermine efficiency gains.

Missenard’s work reminds us that comfort is a physical quantity that can be measured, optimised, and designed for. By delivering genuine comfort at lower energy input, °M-based design aligns perfectly with decarbonisation goals.

Educational and professional continuity

In France, the COSTIC continues to teach °M alongside PMV/PPD, especially in courses on renovation and system balancing (COSTIC, 2021). The historical framing is often absent, but the method persists because it works. Engineers still appreciate the immediacy: no modelling software, no large datasets—just measured values, a quick calculation, and a clear answer.

Where PMV/PPD fits today

In high-performance new builds with controlled environments, PMV/PPD remains a useful design and compliance tool. But in existing buildings with varied conditions, °M can be more diagnostically revealing. The two can be complementary:

- Use °M to assess current comfort and guide retrofit decisions.

- Use PMV/PPD to model post-renovation comfort and ensure compliance with standards like ISO 7730 or ASHRAE 55.

Missenard logic: diagnose comfort as a physical reality, then engineer to match it, not just to hit an air temperature.

A method for the decarbonisation era

As we retrofit millions of buildings for net-zero targets, the lessons of Missenard are clear:

- Measure comfort fully — include radiation, not just air.

- Design for °M, not just °C — integrate comfort into hydraulics and emitter strategy.

- Use simplicity as a strength — tools that work in the field are more likely to be applied consistently.

In this way, a French engineer from the 1930s speaks directly to our 21st-century challenges: achieving comfort with less energy, through intelligent integration of measurement, physics, and practical design.

X — Conclusion — A French Invention, a Global Language

André Missenard’s career reads like a quiet revolution in building engineering. He did not coin a fashionable term or patent a single defining invention. Instead, he redefined how comfort could be measured, and in doing so, set the stage for an entire generation of predictive modelling and international standards.

From the 1933 publication of the température résultante (Missenard, 1933) to the practical elegance of the °M index, he bridged the gap between physics and practice. His work placed radiant temperature—the often invisible half of our thermal environment—on equal footing with air temperature. This was not an academic indulgence; it was an operational necessity for the heating engineers of his time, and it remains so for those designing low-carbon systems today.

The chain of influence is undeniable:

- Missenard provided the measurement framework, complete with instruments, nomograms, and on-site methodology.

- Scandinavian and German researchers reformulated it as “operative temperature” in laboratory terms.

- Fanger incorporated it into the environmental variables of his PMV/PPD model (Fanger, 1970).

- ASHRAE and ISO adopted these models, making them the lingua franca of comfort engineering.

Somewhere along that chain, the name “Missenard” was lost. Operative temperature became a technical descriptor divorced from its French roots. PMV/PPD became “the standard” without reference to the man whose measuring stick made it possible. In English-language literature, the origin story is often reduced to a parenthetical note—if it appears at all.

This article has been, in part, an attempt to put that name back where it belongs.

Why it matters now

Revisiting Missenard is not a nostalgic exercise. It is about using the right tools for the right job. In the decarbonisation era, °M offers a straightforward, field-ready method for diagnosing and improving comfort in existing buildings—especially those where radiant losses dominate. It can guide retrofit priorities, optimise low-temperature systems, and ensure that comfort and efficiency rise together.

In other words: PMV/PPD may be the global language of comfort, but °M remains its French accent—practical, direct, and rooted in the reality of lived spaces.

A personal note

I first met Missenard in the hydraulic schematics of my student years, long before I understood his role in comfort science. Later, in the comfort and health modules of my specialisation, I rediscovered him—not as a name in a diagram, but as an engineer who had quietly given the profession a way to see and measure what people actually feel.

In that sense, Missenard’s greatest legacy is not just the °M index or the thermometer that bears his name. It is the idea that comfort is a physical quantity that can be captured, understood, and engineered—not guessed at or left to chance.

If the world’s standards now speak the language of operative temperature, let us remember that the dictionary was written in French.

References

- AFNOR (1956). Norme NF X35 — Ambiances thermiques et hygrothermiques: critères de confort thermique dans les bâtiments. Paris: Association Française de Normalisation.

- ASHRAE (1981). ANSI/ASHRAE Standard 55-1981: Thermal Environmental Conditions for Human Occupancy. Atlanta, GA: American Society of Heating, Refrigerating and Air-Conditioning Engineers.

- ASHRAE (2017). ANSI/ASHRAE Standard 55-2017: Thermal Environmental Conditions for Human Occupancy. Atlanta, GA: American Society of Heating, Refrigerating and Air-Conditioning Engineers.

- Bedford, H.T. (1940). Globe Thermometer for the Measurement of Mean Radiant Temperature. Journal of the Institution of Heating and Ventilating Engineers, 7(3), pp. 76–80.

- COSTIC (1948). Bulletin Technique du Comité Scientifique et Technique des Industries Climatiques. Paris: COSTIC.

- COSTIC (2021). Formation: Confort thermique et santé. Paris: COSTIC.

- CSTB (1959). Rapport sur la Température Résultante et l’Application dans le Bâtiment. Paris: Centre Scientifique et Technique du Bâtiment.

- Fanger, P.O. (1970). Thermal Comfort: Analysis and Applications in Environmental Engineering. Copenhagen: Danish Technical Press.

- Houghton, F.C. & Yaglou, C.P. (1923). Determining Equal Comfort Lines. Transactions of the American Society of Heating and Ventilating Engineers, 29, pp. 163–176.

- Missenard, A. (1933). Température effective d’une atmosphère. Généralisation température résultante d’un milieu. Encyclopédie Industrielle et Commerciale, Série B, Paris.

- Missenard, A. (1935). Le degré Missenard et ses Applications. Bulletin Technique du COSTIC, Paris.

- Missenard, A. (1938). Le Chauffage par Planchers Rayonnants. Bulletin Technique du COSTIC, Paris.

- Vernon, T.H. (1930). The Globe Thermometer and Its Use in Studies of Thermal Comfort. Medical Research Council, Industrial Fatigue Research Board Report No. 47, London: HMSO.