Electronics Manufacturing Energy Audit

Comprehensive Level 2 energy audit for a manufacturing facility producing Square Nano, TR/TE, Molding, and PICO products. The audit focused on HVAC systems, compressed air networks, water heating, and lighting—identifying opportunities to reduce energy use, improve environmental performance, and maintain operational reliability across production, office, and laboratory areas.

Detailed Assessment

- Review of DX cooling systems, AHUs, and control sequences.

- Compressed air analysis for leak prevention, load optimization, and control efficiency.

- Evaluation of water heating systems for operational efficiency.

- Facility/office lighting assessment for technology and control upgrades.

Performance Evaluation

- Optimization of HVAC temperature setpoints and operational control sequences.

- Shutdown protocols for exhaust fans during non-production periods.

- Compressed air pressure optimization to match equipment requirements.

- Efficiency improvements to air-cooled process chillers.

- Installation of variable speed drives (VSDs) on ventilation fans.

- Water heating optimization in support facilities.

- Major HVAC upgrades: transition to water-cooled chillers; replacement of AHUs with outdoor-rated units.

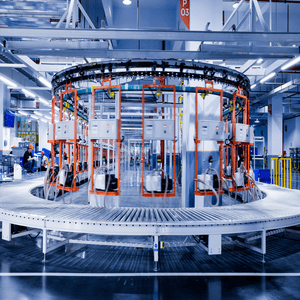

- Integration of process cooling into a centralized water-to-water chiller system.

Diagnostic Testing

- Verification of control adjustments for temperature, airflow, and pressure setpoints.

- Compressed air leak detection and pressure stability testing.

- Measurement of chiller and AHU performance post-upgrade.

Maintenance Review

- Updated preventive maintenance for chillers, AHUs, compressors, and VSDs.

- Operator training on optimized setpoints, shutdown procedures, and system monitoring.

- Regular performance checks integrated into facility maintenance routines.

System Optimization

- Load-matched chiller operation; centralized process cooling integration for higher efficiency.

- BMS-driven control logic to balance energy savings with production stability.

- Reduced ventilation and compressed air waste via improved scheduling.

Efficiency Improvement

- Estimated Annual Energy Savings: 2,411 MWh.

- CO₂ Emissions Reduction: 1,548 tonnes/year.

Result: Facility-wide optimization delivering substantial energy and carbon reductions, while upgrading core HVAC and ventilation systems to modern, high-efficiency standards that support both manufacturing and laboratory requirements.